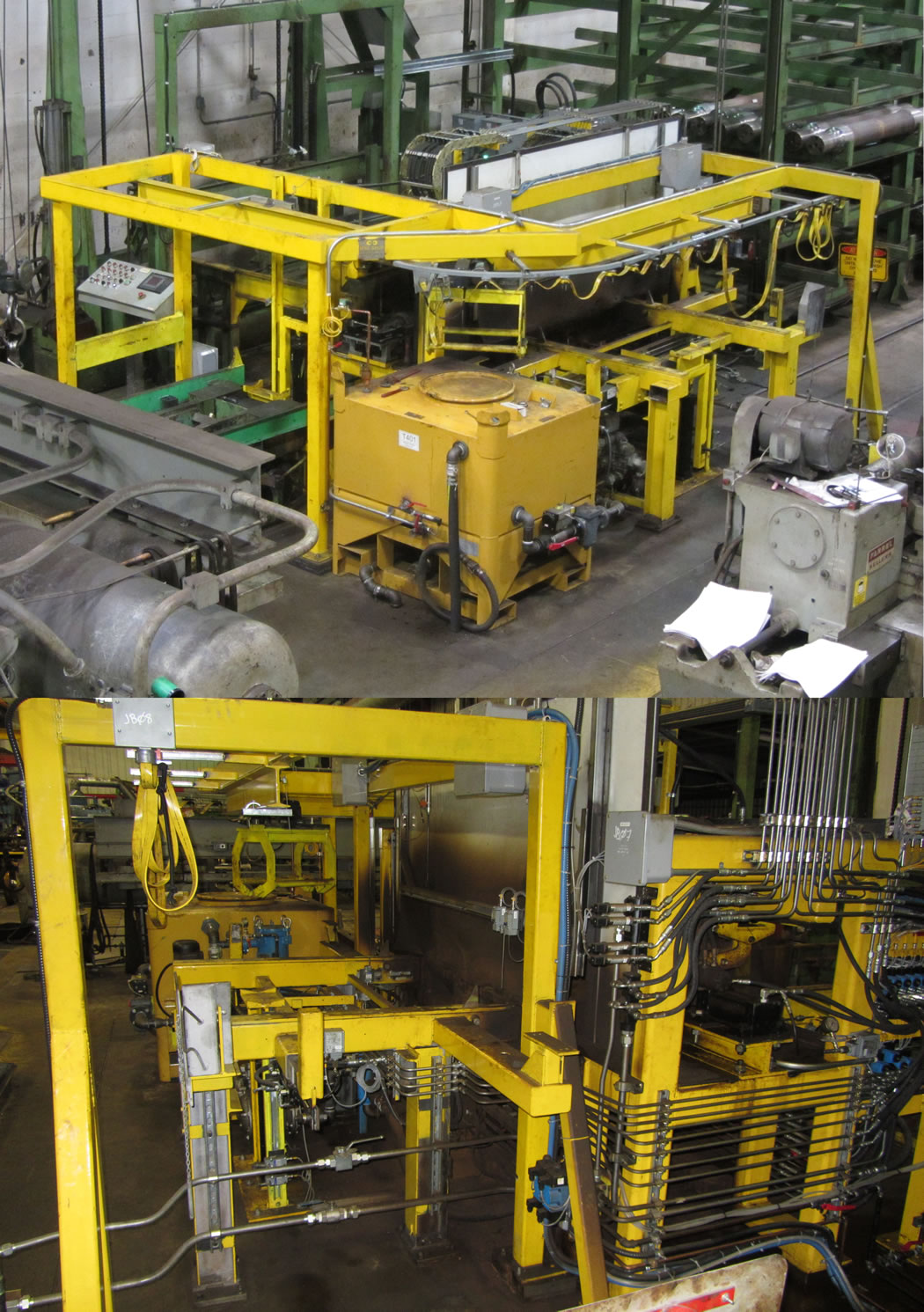

Automatic Axle Wash Systems

A fully automated machine that transfers dirty rail car axles into the wash chamber for a thorough mechanical and chemical scrubbing process. Cleaned axles are ejected to continue down the production line via tight integration with the rest of the wheel shop.

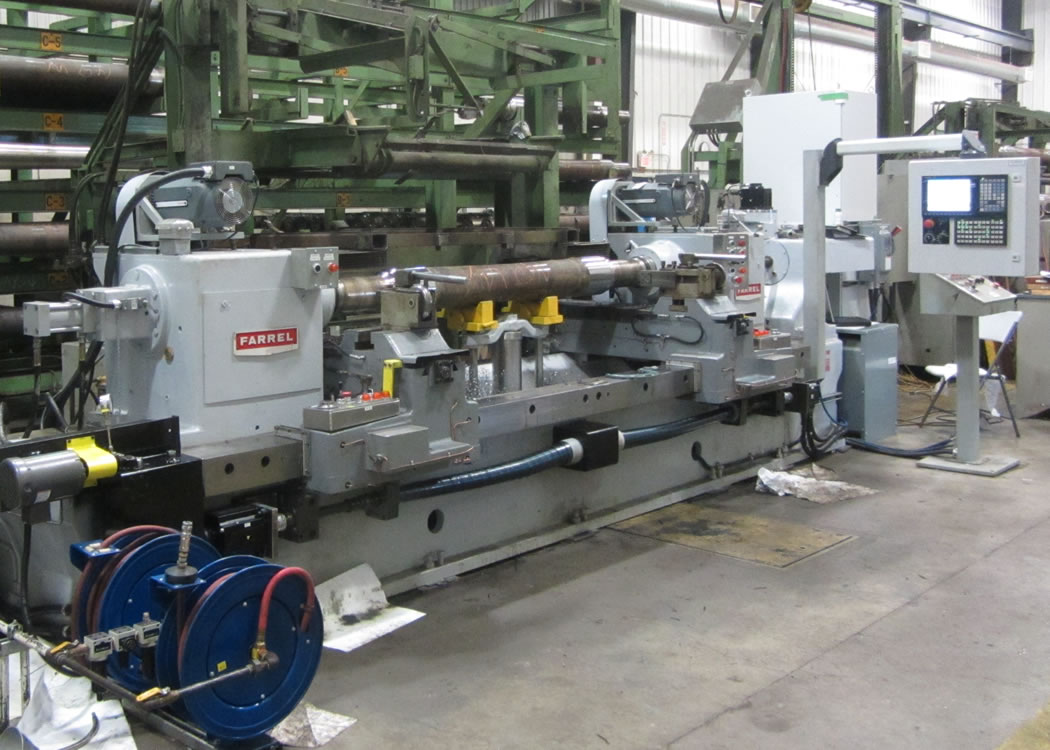

CN Prince George Axle CNC Lathes

Complete modernization of two existing wheel axle lathes. New CNC system automatically cuts the required profile for mounting wheels.

CN Transcona Wheel Truing Machine Repair

Project management, hydraulic, electrical and mechanical repair of a specialized rail wheel metal lathe. The wheel truing machine is the workhorse of rail wheel repair. Over a two year period LRDL reviewed the maintenance and operability of the lathe, procured critical parts and set up a heavy repair program to repair the lathe and restore production rates.

CN Prince George Wheel Shop

Complete relocation of former BCRail wheel shop from Squamish to Prince George. Optimized flow of wheel blanks, axles, and wheelsets through shop. Provided complete controls system, including automated handling of material from storage racks to carts and conveyors. Coordinated logistics of move.

CN MacMillan Wheel Shop — Wheel Truing Line Vaughan, Ontario

Phase one wheel turn line of a two phase automated freight wheel shop. Wheel shop is built in a low ceiling warehouse utilizing automated material handling conveyors, automatic bearing removal, wheel set washing and inspection to qualify axle and wheels. Wheel sets are sorted into horizontal short run queues prior to processing. All new automated equipment for truing of wheel treads, ultrasonic inspection and bearing installation.

LRDL provided overall shop layout, project construction management, project budget and planning, assisted with equipment specification and procurement. LRDL designed, constructed and installed wheel advancers and lateral chain conveyors.